- Overview

- Details

- The Opportunity

- A Federated Footprint and Operating Model

- The Zen of Fiscal Stewardship in Maintenance Management

- BUILDER: A Consistent View of the Enterprise

- Change is a Difficult Proposition—How to Achieve Stakeholder Buy-In

- The Support to Overcome Challenges

- Building on BUILDER’s Value Proposition

- Guidance references

BUILDER: A Science-Based Approach to Infrastructure Management

Overview

The Department of Energy’s National Nuclear Security Administration (NNSA) adopted a data-driven, risk-informed strategy to better assess risks, prioritize investments, and cost effectively modernize its aging nuclear infrastructure. NNSA’s new strategy, and lessons learned during its implementation, will help inform other federal data practitioners’ efforts to maintain facility-level information while enabling accurate and timely enterprise-wide infrastructure analysis.

Source

Category

Keywords

Details

Originally published July 19, 2019

The Opportunity

When organizations defer maintenance and repair of buildings and other infrastructure they usually incur additional costs and risks. To help address this issue, the Department of Energy’s National Nuclear Security Administration (NNSA) adopted a data-driven, risk-informed strategy to better assess risks, prioritize investments, and cost effectively modernize its aging nuclear infrastructure. NNSA’s new strategy, and lessons learned during its implementation, will help inform other federal data practitioners’ efforts to maintain facility-level information while enabling accurate and timely enterprise-wide infrastructure analysis.

“Traditionally, infrastructure management was done by looking in the rearview mirror. With our new strategy, we are turning that around, to look out the front windshield. We see obstacles coming our way and proactively adjust to meet and overcome them.”

— Tyson Deschamp (Deputy Director, Office of Infrastructure Planning & Analysis)

A Federated Footprint and Operating Model

The NNSA is responsible for enhancing national security through the military application of nuclear science. Its roughly 44,000 federal and contractor employees maintain the safety, security, and effectiveness of the U.S. nuclear weapons stockpile, work to reduce and prevent nuclear weapons proliferation, play a pivotal role in countering and responding to nuclear terrorism, and continue to provide safe, militarily-effective nuclear propulsion reactors to the U.S. navy.

To accomplish its mission, the NNSA operates and maintains a vast and complex portfolio of cutting-edge research and development laboratories, manufacturing and production facilities, and mission-enabling infrastructure located across eight primary sites. NNSA’s Office of Safety, Infrastructure, and Operations (NA-50) is responsible for ensuring that this portfolio of land, roads, utilities, and facilities is able to safely and effectively conduct its mission as one of America’s premier assets for science, technology, innovation, and national security. Each of these sites is managed and operated by contractors who receive funding from the NNSA to maintain and operate equipment and buildings.

Managing such a diverse portfolio can make prioritization of required maintenance a difficult task. Traditionally, each contractor uses unique computerized maintenance management systems customized to their site-specific needs. This method, while acceptable and successful at the site-level, makes it nearly impossible to credibly aggregate the total output into an NNSA-wide analysis of infrastructure maintenance needs in both the near- and long-term.

“The short-term needs of today often take priority over the long-term needs of the future. This is a large challenge we face with infrastructure.”

— Jessica Kunkle (Director, NA-50 Program Management Office)

The Zen of Fiscal Stewardship in Maintenance Management

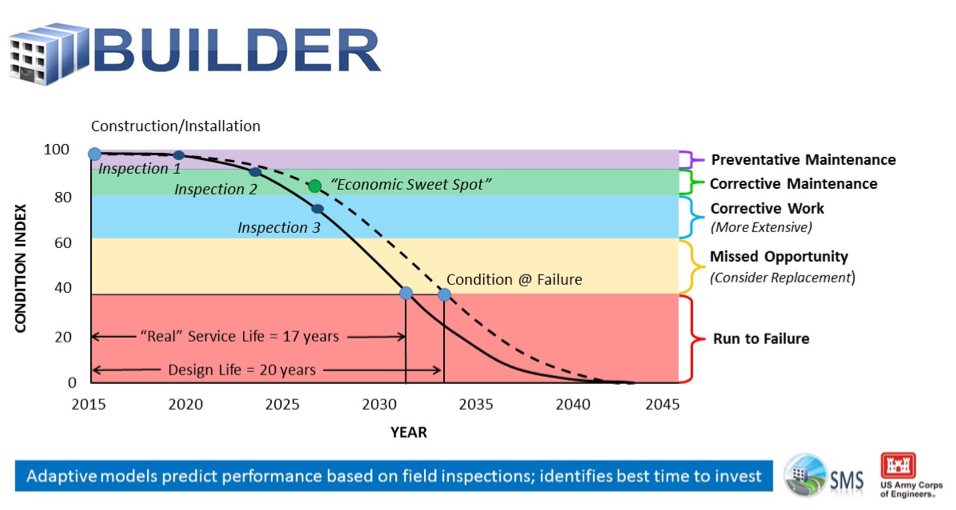

Infrastructure typically, though not always, degrades at a slow, predictable rate. Maintenance management, then, is all about managing risk. While choosing not to refurbish your roof regularly may save money in the short-term, each year of deferring maintenance increases the risk of a total roof failure. It is cheaper to do some maintenance along the way to extend the roof’s useful life, rather than replace the entire roof.

Each year, NNSA must make difficult decisions about which maintenance and repair investments should be executed and which can be safely deferred. These daily trade-offs that ultimately result in deferring certain maintenance activities were made at the site level and allowed each site to maximize risk buy-down. However, this compartmentalized process did not allow NNSA to optimize risk buy-down across the enterprise. Inevitably, questions arose that were difficult to answer at the enterprise level, such as, “How much enterprise risk would we be accepting in hypothetical scenario ‘X’?” Given the inconsistent systems used across the enterprise, NNSA could only estimate the enterprise risk under a specific funding scenario. With its aging infrastructure, NNSA knew it needed to implement a new approach to analyzing and prioritizing these investments.

“Our sites operate as a network—as a supply chain. We need to make sure we evaluate the system as a whole, not just each site individually.”

— Jessica Kunkle (Director, NA-50 Program Management Office)

BUILDER: A Consistent View of the Enterprise

To meet this challenge NNSA began implementing the BUILDER Sustainment Management System, integrating each site’s existing processes into a standardized, enterprise-wide system. BUILDER is a software program that helps NNSA proactively respond to emerging infrastructure needs by recommending building component repairs and replacements at the most opportune time, thus ensuring the greatest return on investment and maximizing risk buy-down given limited resources. BUILDER provides the NNSA with a single, rules-based approach to assess infrastructure and inform renewal decisions based on current and predicted system conditions, functionality, mission priorities, and acceptable risk tolerance levels. Developed by the U.S. Army Corps of Engineers (USACE), BUILDER has been recognized by the National Academies of Science as a best‐in‐class practice for infrastructure management.

BUILDER Component Lifecyle Condition Curve.

In 2014, NNSA entered into a partnership with USACE, procuring the BUILDER software and Enterprise implementation support services. This program laid the foundation for the NNSA to accurately, repeatedly, and quickly provide enterprise-wide maintenance and repair forecasts, now and into the future, under any number of scenarios.

“We compete for the same budget as other critical missions. Before we invested in BUILDER, we could tell executive leadership that cutting our budget will increase risk, but we couldn’t know specifics. Now, we can model investment scenarios to effectively and precisely quantify the risks and impacts.”

— Tyson Deschamp (Deputy Director, Office of Infrastructure Planning & Analysis)

But getting the software was just the beginning. Optimizing the full capabilities of BUILDER required careful coordination with USACE, NNSA sites, and third-party contractors and a significant culture change within NNSA.

Change is a Difficult Proposition—How to Achieve Stakeholder Buy-In

The NA-50 team is nearly five years into its six-year implementation plan. While progress has not always been easy, the most difficult hurdles are in the past. The greatest initial challenge was gaining stakeholder buy-in from sites that struggled to recognize the value in shifting historical, site-efficient processes to support a broader, enterprise-wide way of doing business. This shift exposed opportunities for improvement in many of the existing site infrastructure management processes and, in some instances, meant establishing processes that did not exist. Understanding the challenges and the varying “starting points” for each of the sites, NA-50 launched a comprehensive implementation program which included forming a cross-functional team with representatives from each site, USACE, NNSA leadership, and various support contractors to create a shared framework accommodating each site’s unique needs. NA-50 also conducted training and empowered sites to host rotating BUILDER team meetings, which fostered a collaborative working relationship. As early adopters began reaping the benefits of more accurate, consistent, and reliable infrastructure data, reluctance gave way. The sites have also benefitted from increased appropriations for maintenance and from new Congressional authorities that resulted from NNSA’s new approach.

The Support to Overcome Challenges

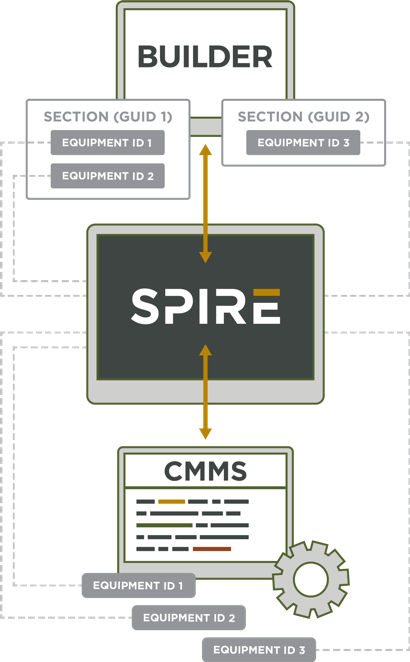

BUILDER - CMMS Integration through SPIRE.

In addition to the challenge of change aversion, integrating BUILDER required navigating several procedural hurdles. For example, while BUILDER captures infrastructure data at the component level, it is primarily a strategic forecasting tool and was not developed to track daily maintenance activities. Therefore, sites use their own unique Computerized Maintenance Management Systems (CMMS) to bridge this gap and manage day-to-day, tactical work actions. These CMMS programs, which help the sites maintain effective operations through features like preventive maintenance scheduling and work order management, receive valuable information that supports BUILDER, but the CMMS data gathering and management practices vary across NNSA.

In order to sync each site’s individual CMMS program with BUILDER, translation software, like DIGON System’s Spire, had to be developed to ensure data was kept up-to-date and accurate. NA-50’s BUILDER team partnered with private companies to overcome such challenges. Software integration significantly reduced data input time and increased data integrity by simultaneously pushing data updates from one system to another, eliminating the need to duplicate changes in both systems.

“It wasn’t like we had a cookbook that we could execute step by step from another agency—we were blazing a new trail as we went—the system integrations, new software extensions, and complex configurations, none of that was foreseen on day one.”

— Tyson Deschamp (Deputy Director, Office of Infrastructure Planning & Analysis)

Building on BUILDER’s Value Proposition

NNSA’s innovative strategies lead the way in federal infrastructure management, and NA-50 welcomes collaborative knowledge-sharing sessions with other agencies to devise new ways to effectively arrest the decline of the nation’s aging, nuclear infrastructure. For those eager to implement their own enterprise-focused program, NA-50 recommends: establishing a clear vision for the use of the program; engaging all stakeholders early in the process from the field to the Hill; empowering field personnel to generate solutions; conducting regular training; hosting frequent team meetings/workshops; hiring experienced software support agents; maintaining an agile framework flexible to changing work requirements and mission needs; implementing stringent data standards and validation procedures; and ensuring transparent communications about the challenges faced with implementation and throughout the process.

“It is critical that we work together to modernize infrastructure to safely meet twenty-first century challenges. Together, we will reverse the decline of our infrastructure and provide a secure future for science, technology, and innovation in the service of national security.

— James J. McConnell (Associate Administrator for Safety, Infrastructure, and Operations)

Postscript

If you would like to learn more about NNSA’s work with BUILDER, please contact Kathryn.Hewitt@nnsa.doe.gov. For media inquiries, please contact NNSAnews@nnsa.doe.gov.

To receive updates on activities related to the Federal Data Strategy, please sign up for the newsletter.

The Federal Data Strategy Incubator Project

The Incubator Project helps federal data practitioners think through how to improve government services, enabling the public to get the most out of federal data. This Proof Point and others will highlight the many successes and challenges data innovators face every day, revealing valuable lessons learned to share with data practitioners throughout government.

Guidance references

- FDS Practice 04 Use Data to Guide Decision-Making

- FDS Practice 10 Provide Resources Explicitly to Leverage Data Assets

- FDS Practice 18 Manage with a Long View

- FDS Practice 22 Identify Opportunities to Overcome Resource Obstacles

- FDS Practice 27 Increase Capacity for Data Management and Analysis

- FDS Practice 36 Leverage Partnerships

- FDS Practice 40 Support Non-Federal Stakeholders

- FDS Principle 08 Invest in Learning

- FDS Principle 10 Practice Accountability